- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

-

The 5-Minute, 5-Things Ring

by Judy Ellis, Wire-Sculpture.com Daily Wire Jewelry Tip May 15th, 2015 A 5-Minute Project for 5-15-15...

-

NEW Products for Spring

New Product Tip March 27, 2015 NEW Wire Jewelry Products! We are always adding new...

-

Spring Cleaning… Ring Cleaning!

by Judy Ellis, Wire-Sculpture.com Daily Wire Jewelry Tip February 17, 2015 Spring Cleaning… Ring Cleaning! It...

-

2014 Craft Wire Contest Winners!

by Judy Ellis, Wire-Sculpture.com Tip for April 9, 2014 Craft Wire Contest Winners! We’ve held contests...

-

Jewelry Resource Dec. 19: Wired Christmas Patterns

by Rose Marion, Wire-Sculpture.com Wire Jewelry Resource for December 19, 2012 Christmas Wire Jewelry Patterns This...

-

Free Resources on Wire-Sculpture, and How YOU Can be Featured!

by Rose Marion, Wire-Sculpture.com I wanted to take just a minute and highlight some of the...

-

Free Wire Jewelry References, Patterns & Inspiration on Wire-Sculpture.com

by Rose Marion, Wire-Sculpture.com Dale’s taking the week off to be with her family, helping her...

-

Daily Wire Tip June 23: Button Wire Jewelry Ideas

Daily Wire Jewelry Making Tip for June 23, 2011 Question: I have several buttons that I’ve...

-

Daily Wire Tip May 30: Wire Jewelry to Make as You Sell

Daily Wire Jewelry Making Tip for May 30, 2011 Question: Hi Dale, now that we are...

-

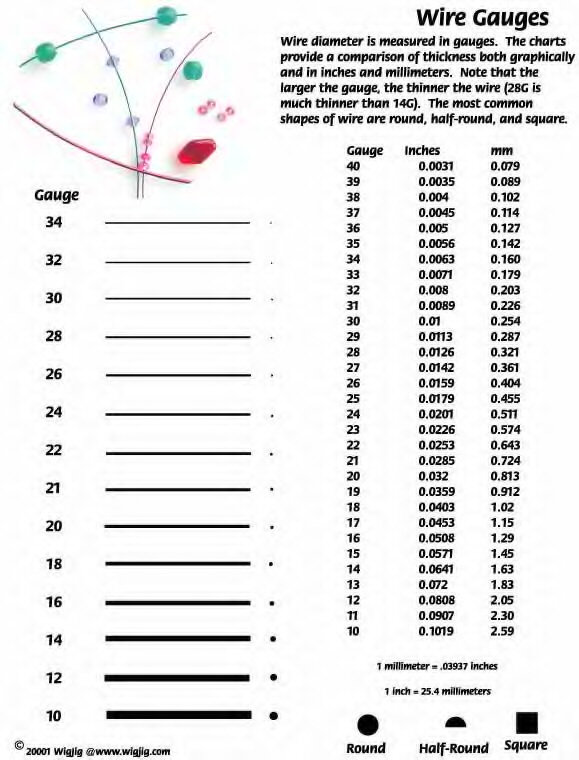

Daily Wire Tip: Projects with 18-Gauge Wire

Daily Wire Jewelry Making Tip December 7, 2010 Question: I made a mistake, and bought multiple...

Featured Tools

-

Get to Know Your Hand Tools – Tube-Cutting Jig By Helen I. Driggs

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for August 4th, 2017 Get...

Wire Jewelry Projects

Design & Inspiration

-

Free Pattern: Smile Cluster Necklace by Karen Meador

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for August 7th, 2017 Smile Cluster Necklace...

- August 7, 2017

- 2

-

Free Pattern: Long crystal round maille earrings by Kylie Jones

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for August 3rd, 2017 Long crystal round...

- August 3, 2017

- 1

-

Free Pattern: Stone Twist Wrap by Karen Meador

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for July 31st, 2017 Stone Twist Wrap...

- July 31, 2017

- 0

-

Free Pattern: Floating Bead Earrings By Kimberly Newman

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for July 27th, 2017 Floating Bead Earrings...

- July 27, 2017

- 2

Free Wire Jewelry Videos

-

Wire Jewelry Video: Using Punch Pliers by Judy Freyer Thompson

Wire Jewelry Video: Using Punch Pliers by Judy Freyer Thompson

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for August 2nd,...

- August 2, 2017

- 0

-

Wire Jewelry Video: Aligning a Hole Punch by Judy Freyer Thompson

Wire Jewelry Video: Aligning a Hole Punch by Judy Freyer Thompson

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for July 26th,...

- July 26, 2017

- 0

Latest News

-

See Yourself as a Creative Thinker-Part IV By Karen Meador, PhD

Wire Jewelry Article for September 27th, 2017 If you missed Part 1, Part 2, or Part 3 of the series you can click here. We occasionally need a...

- September 27, 2017

- 0

-

Simple Soldering Station By Denise Peck

Wire Jewelry Tip for September 22nd, 2017 Simple Soldering Station by Denise Peck If you’re venturing into soldering with a handheld butane torch, there are a few things you...

- September 22, 2017

- 0

-

See Yourself as a Creative Thinker-Part III By Karen Meador, PhD

Wire Jewelry Article for September 20th, 2017 If you missed Part 1 and Part 2 of the series you can click here. Fluency, Flexibility, Originality, Elaboration and Resistance...

- September 20, 2017

- 0

-

Make a Three-Strand Bracelet by Marilyn Gardiner

Wire Jewelry Tip for September 19th, 2017 Make a Three-Strand Bracelet by Marilyn Gardiner You often see 3-strand beaded bracelets, but have you considered making one with chainmail? There...

- September 19, 2017

- 0

-

Making Paddle Ends By Denise Peck

Wire Jewelry Tip for September 15th, 2017 Making Paddle Ends by Denise Peck Flattening the ends of wire into a paddle shape is a versatile technique that’s quite handy...

- September 15, 2017

- 0

-

See Yourself as a Creative Thinker-Part II By Karen Meador, PhD

Wire Jewelry Article for September 13th, 2017 If you missed Part 1 of this series, you can find it here! Brainstorming See yourself as creative and you will likely...

- September 13, 2017

- 0

-

Handy Uses for the WireJewelry.com Cushion Clamp By Karen Meador, PhD

Wire Jewelry Tip for September 12th, 2017 Handy Uses for the WireJewelry.com Cushion Clamp by Karen Meador, PhD There are definitely times when I need an extra hand or...

- September 12, 2017

- 0

-

Making Perfect Eye Pins by Delilah

Wire Jewelry Tip for September 8th, 2017 Making Perfect Eye Pins by Delilah Eye pins are another staple of jewelry making, and another finding that is so simple to...

- September 8, 2017

- 0

-

See Yourself as a Creative Thinker By Karen Meador PhD

Wire Jewelry Article for September 6th, 2017 This is the first in a series of articles about creative thinking and the expression of it in jewelry making. It is...

- September 6, 2017

- 2

-

Perfecting your Wirework By Delilah

Wire Jewelry Tip for September 5th, 2017 Perfecting your Wirework by Delilah If you venture in wire wrapping, make it look perfect! Nothing detracts from a wire piece more...

- September 5, 2017

- 0

-

Make Ear Wires from Headpins or Eye pins! by delilah

Wire Jewelry Tip for September 1st, 2017 Make Ear Wires from Headpins or Eye pins! by delilah If you don’t usually work with wire, or you just happen to...

- September 1, 2017

- 1

-

Kitchen Patinas By Jen VanBenschoten

Wire Jewelry Article for August 30th, 2017 Have you ever wanted to add a lovely patina to your wire jewelry or oxidize your copper and sterling silver without using...

- August 30, 2017

- 0

-

New Pliers for Chain Maille By Marilyn Gardiner

Wire Jewelry Tip for August 29th, 2017 New Pliers for Chain Maille by Marilyn Gardiner I’ve recently acquired 3 new types of pliers for chainmail and I’d like to...

- August 29, 2017

- 0

-

Free Pattern: Embellished Artisan Ear Wires by Abby Hook

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for August 28th, 2017 Embellished Artisan Ear Wires by Abby Hook Jewelry findings can be as ornately decorated as the jewelry they...

- August 28, 2017

- 0

-

Make perfect loops settings for your projects with skewers! By Delilah

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for August 25th, 2017 Make perfect loops settings for your projects with skewers! by Delilah Every now and then, you may find...

- August 25, 2017

- 1

-

Free Pattern: Embellished Heart Earrings by Abby Hook

by Judy Ellis, Wirejewelry.com Wire Jewelry Pattern for August 24th, 2017 Embellished Heart Earrings by Abby Hook By attaching faceted briolettes to a hammered heart frame, you can create...

- August 24, 2017

- 1

Explore Wire Jewelry Tips by Month

Jewelry Topics

Search

Search the Wire Jewelry Blog

Daily Tips

-

See Yourself as a Creative Thinker-Part IV By Karen Meador, PhD

Wire Jewelry Article for September 27th, 2017 If you...

- September 27, 2017

- 0

-

Simple Soldering Station By Denise Peck

Wire Jewelry Tip for September 22nd, 2017 Simple Soldering Station...

- September 22, 2017

- 0

-

See Yourself as a Creative Thinker-Part III By Karen Meador, PhD

Wire Jewelry Article for September 20th, 2017 If you...

- September 20, 2017

- 0

-

Make a Three-Strand Bracelet by Marilyn Gardiner

Wire Jewelry Tip for September 19th, 2017 Make a Three-Strand...

- September 19, 2017

- 0

-

Making Paddle Ends By Denise Peck

Wire Jewelry Tip for September 15th, 2017 Making Paddle Ends...

- September 15, 2017

- 0

Promotions

-

JOGS 2017 – Chain mail, wrapping and beading

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for December...

- December 5, 2016

- 0

-

JOGS 2017 – Color on Metal and Beads

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for November...

- November 28, 2016

- 0

-

JOGS 2017 – Metal Sheet and Chainmail

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for November...

- November 21, 2016

- 0

-

Explore JOGS Instructors

by Judy Ellis, Wirejewelry.com Wire Jewelry Tip for October...

- October 3, 2016

- 0

-

See Yourself as a Creative Thinker-Part IV By Karen Meador, PhD

Wire Jewelry Article for September 27th, 2017 If...

- September 27, 2017

- 0

-

See Yourself as a Creative Thinker-Part III By Karen Meador, PhD

Wire Jewelry Article for September 20th, 2017 If...

- September 20, 2017

- 0

-

See Yourself as a Creative Thinker-Part II By Karen Meador, PhD

Wire Jewelry Article for September 13th, 2017 If you...

- September 13, 2017

- 0

-

See Yourself as a Creative Thinker By Karen Meador PhD

Wire Jewelry Article for September 6th, 2017 This is...

- September 6, 2017

- 2

-

Gem Profile Contest: Name That Rock! (Contest is Over)

by Rose Marion, Wire-Sculpture.com Gem Profile Contest forApril 13,...

- April 13, 2012

- 92

-

Daily Wire Tip: Prevent Tarnish on Copper and Nickel Silver

Daily Wire Jewelry Making Tip Question: This is not...

- September 4, 2010

- 86

-

Gem Profile Contest! Name that Rock!

by Rose Marion, Wire-Sculpture.com Gem Profile Contest for January...

- January 20, 2012

- 77

-

A message from Rose: Good-bye!

by Rose Marion, Wire-Sculpture.com A message from Rose for...

- November 6, 2013

- 76